CNC Machining and

Precision Engineering

J J Hardy & Sons offer a wide range of CNC machining and precision engineering services, delivering high quality products and solutions to a number of market sectors.

CNC Machining Services

J J Hardy & Sons specialise in CNC machining techniques and technology, using CNC turn and mill machines to manufacture precision parts and components for leading companies, ensuring they meet the most stringent of industry standards

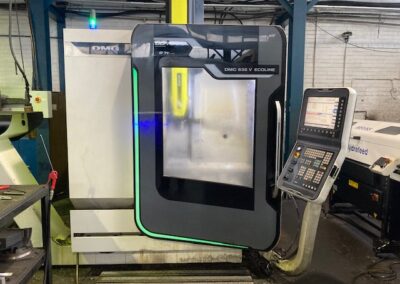

We have a commitment to constant innovation and have continually invested in the latest CNC machining technology. This commitment has seen us invest in the following machine tools including our first additive manufacturing 3d printer

Precision Engineering Services

Mitutoyo co-ordinate measuring machine

This is used to inspect parts up to a maximum size X 330.0mm Y 310.0mm Z 200.0mm using the latest quality control technology software.

- On-line measurements

- Dimensional inspections

- CAD-to-part comparisons

- Reverse engineering

Other major items of inspection equipment include:

- Mitutoyo Ark-600 – hardness testing machine

- Trimoss electronic height gauge – max. height 150mm

- Tessa surface finish measuring equipment

- Baty Shadowgraph

Additive Manufacturing

Our state-of-the-art Ultimaker S5 means we can produce precision components and parts, not only in mass, but also at a significantly lower cost compared to traditional forms of production.

CAD/CAM

J J Hardy boasts a team of in-house CAD/CAM specialists who love nothing more than helping clients bring their ideas to life through the use of market-leading Autodesk software.

The firm was founded by John James Hardy in 1856 at Bond St. Hartlepool. The company prospered and moved to Throston Bridge in the 1880s. W.H. Hardy (Billy) took over as M.D. on his fathers death and continued in that position until 1937 when he sold the company to T.H. Pailor.

Ald. T.H. Pailor bought the company, limited liability since 1929, and ran it until his death in 1963. His widow, Marion Isobel Pailor, was M.D. until 1967 when his son, Tom Pailor, took over on her death.

Tom supervised the move to Brenda Road and the company’s transition from brassfounders and finishers to CNC machinists and railways parts suppliers. On his retirement in 2002, his son Andrew Pailor became M.D. – only the sixth person to hold this position in 150 years.

Quality service & skills

- ISO 9001:2015 – accreditation since 1990 shows our continued commitment to quality

- Autodesk Fusion 360 – rapid programming for even the most complex parts

- Latest CNC machining – our constant investment program ensure we keep our prices competitive

- Highly trained workforce – our modern apprentice program ensures a workforce for the new millennium

Partnership

- Partnership sourcing – working together with our clients we have a policy of continuous improvement

Flexibility

- Batch Sizes 1 to 1000s – our range of CNC machines can satisfy the most demanding production needs

- Reverse engineering for spare parts – give us a sample part and we will make a perfect copy

- Flexible machine tools – rapid set up times enables speedy response

Rail industry approved

- UK rail approvals – a wide range of UK rail approvals are held

- Rail spares – as experts in the field of railway spares we offer an unrivalled service to rail networks

- Wide range of rail parts – always in stock for UK main line and urban railways