About us

Established in 1856, J J Hardy & Sons Limited enjoys a longevity and reputation few other companies can claim to have.

The company started manufacturing as brass founders and general engineers, and has evolved into one of the best equipped CNC machine shops in the United Kingdom. We utilise the latest technology and techniques to keep our services at the forefront of engineering. Quality and customer satisfaction are always our priorities, and we have been ISO 9000 Approved since 1990. You can find details of our equipment and services right here, as well as new developments and the means to get in touch if you have any enquiries or comments.

The History of J J Hardy & Sons

Established in 1856, J J Hardy & Sons has evolved into one of the best equipped CNC machine shops in the UK, utilising the latest technology and techniques to keep our services at the forefront of engineering.

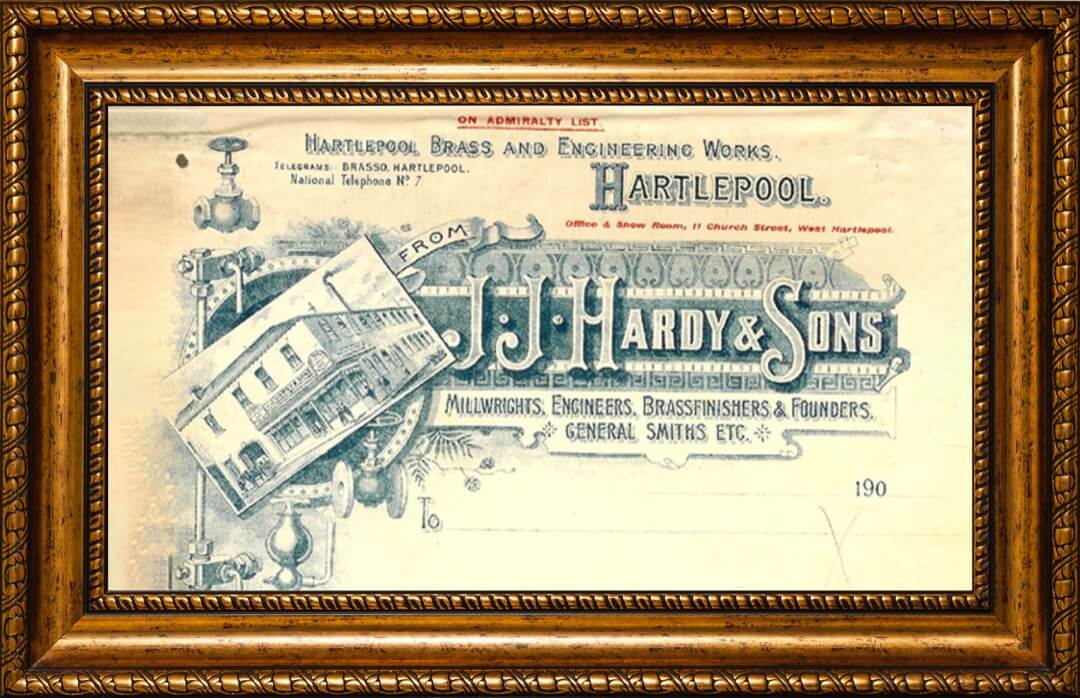

1856

An official letter from Companies House shows that J J Hardy & Sons was founded as a business in 1856. The company started life in the Sunniside area of Hartlepool, which was effectively someone’s back yard.

1870

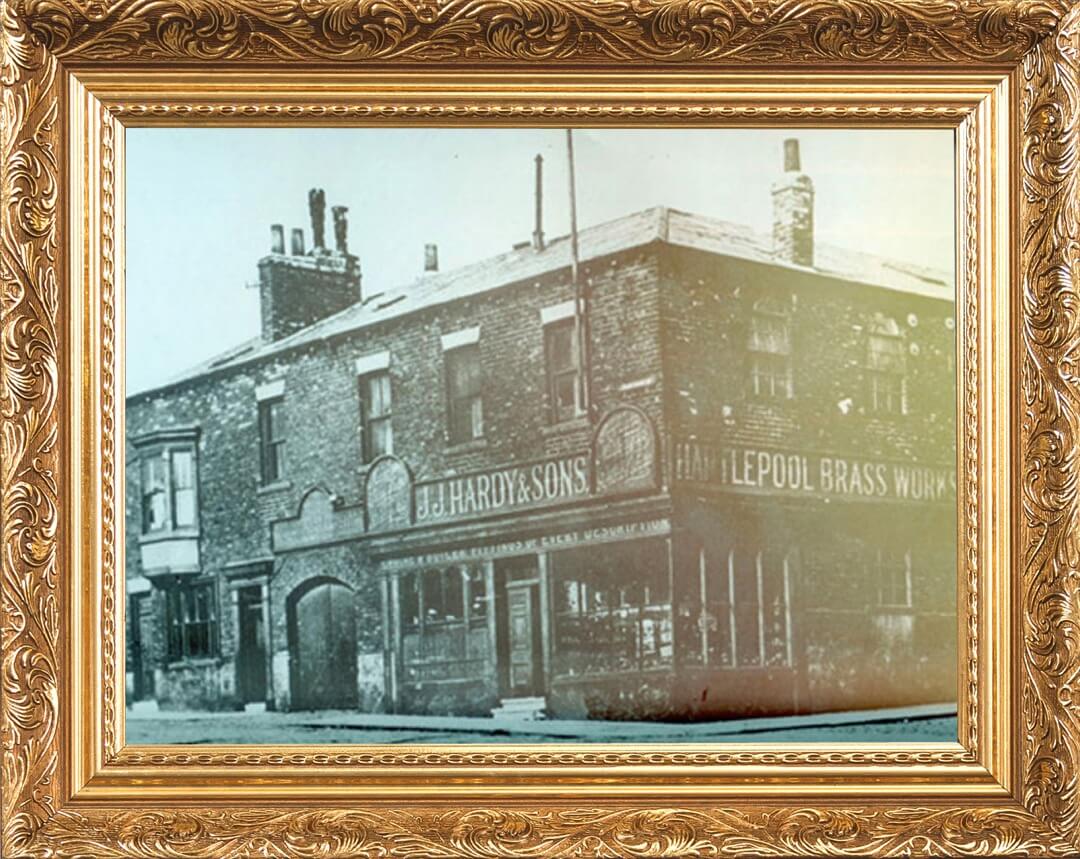

The company then opened its first dedicated workshop in the town in 1870.

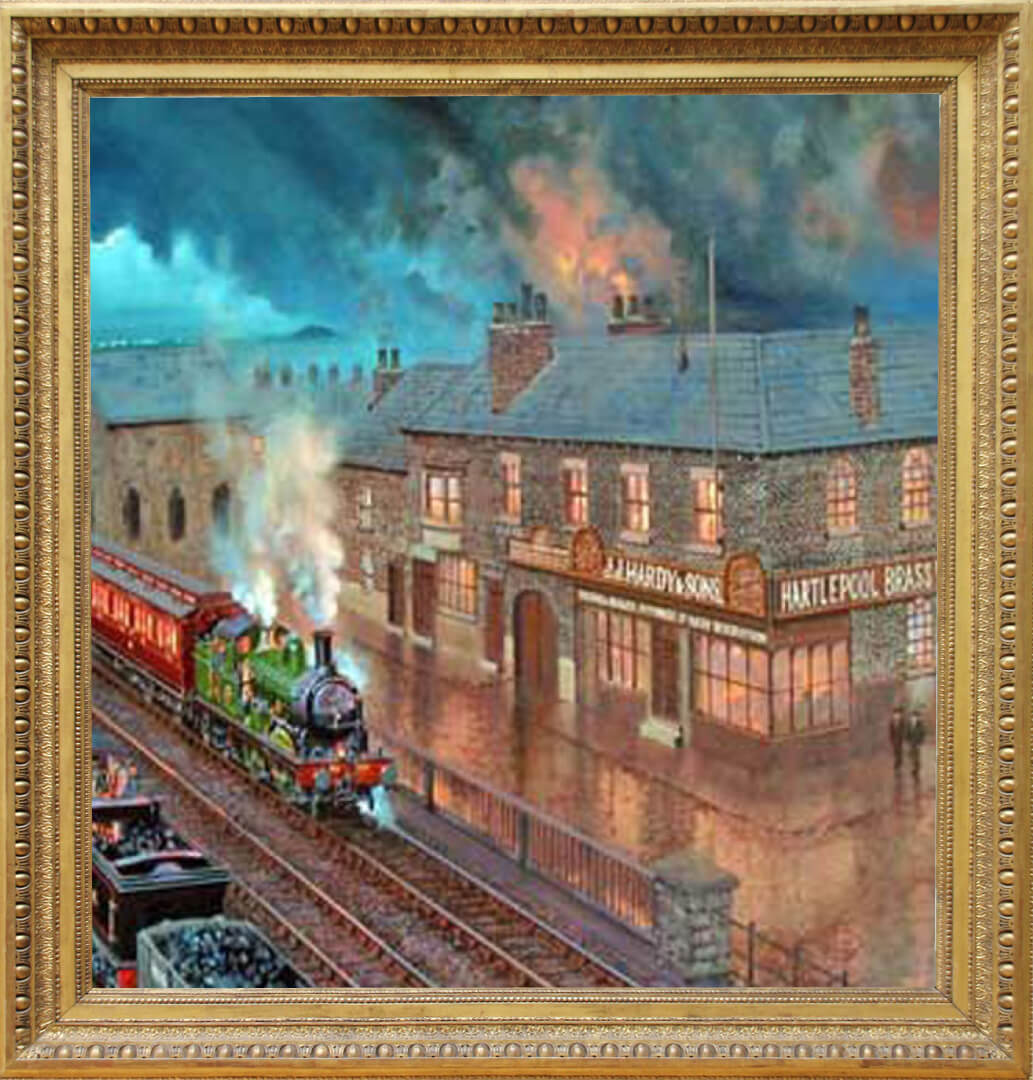

Old building

Located close to the docks and rail links, the new site saw J J Hardy forge a reputation for being a trusted, family business supplying the maritime and rail industries.

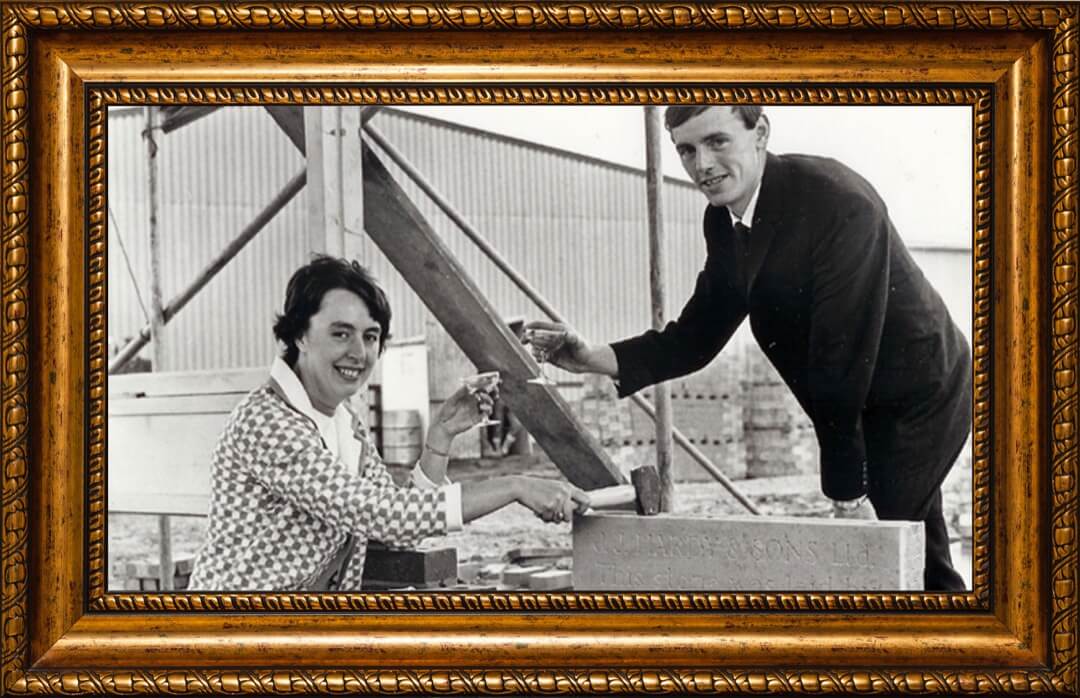

1967

Tom and Madj Pailor laying the stone at the new bespoke facility just off Brenda Road, Hartlepool. Over the next 50 years, this innovative factory saw J J Hardy transformed from a foundry to a CNC machine shop.

NC Paper Tape Machine

A young Andy Pailor, current MD, working an NC paper tape machine at the Brenda Road facility.

Vertical Machining Centre

It wouldn't be long however until winging up axis was no more, as J J Hardy continued to innovate and blaze a trail in the industry with the purchase of one of the UK's first state-of-the-art VMC (Vertical Machining Centre) with 4-axis.

Mazak Machine

Over the coming years, J J Hardy would continue to invest in its market-leading CNC machining to remain at the forefront of industry.

Made in Britain Status

A proud member of Made in Britain, J J Hardy & Sons now flies the flag for UK manufacturing across the globe.

2020

The rise of Industry 4.0 saw the company really embrace digital transformation in 2020, as it worked closely with regional univerisites to invest in the hardware and software required to continue breaking the mould.

2021

A commitment to continue embracing the latest technologies and pioneering new forms of product design and development saw J J Hardy delve into additive manufacturing in 2021 with the purchase of its first 3D Printer, heralding the beginning of a new chapter for the historic business.

The firm was founded by John James Hardy in 1856 at Bond St. Hartlepool. The company prospered and moved to Throston Bridge in the 1880s. W.H. Hardy (Billy) took over as M.D. on his fathers death and continued in that position until 1937 when he sold the company to T.H. Pailor.

Ald. T.H. Pailor bought the company, limited liability since 1929, and ran it until his death in 1963. His widow, Marion Isobel Pailor, was M.D. until 1967 when his son, Tom Pailor, took over on her death.

Tom supervised the move to Brenda Road and the company’s transition from brassfounders and finishers to CNC machinists and railways parts suppliers. On his retirement in 2002, his son Andrew Pailor became M.D. – only the sixth person to hold this position in 150 years.

Why J J Hardy & Sons

Quality service & skills

- ISO 9001:2015 – accreditation since 1990 shows our continued commitment to quality

- Autodesk Fusion 360 – rapid programming for even the most complex parts

- Latest CNC machine tools – our constant investment program ensure we keep our prices competitive

- Highly trained workforce – our modern apprentice program ensures a workforce for the new millennium

Partnership

- Partnership sourcing – working together with our clients we have a policy of continuous improvement

Flexibility

- Batch Sizes 1 to 1000s – our range of CNC machines can satisfy the most demanding production needs

- Reverse engineering for spare parts – give us a sample part and we will make a perfect copy

- Flexible machine tools – rapid set up times enables speedy response

Rail industry approved

- UK rail approvals – a wide range of UK rail approvals are held

- Rail spares – as experts in the field of railway spares we offer an unrivaled service to rail networks

- Wide range of rail parts – always in stock for UK main line and urban railways